I’ll discuss all you need to know about Vacuum Insulating Glass Price plus a few practical tips. Insulated glass is composed of at least 2 panes of glass attached together and sealed around the edges, leaving a layer of space in between. This space is the most important key in preventing condensation inside dual and triple pane glass windows and doors.

Using insulated glass on your wine cellar door is an excellent choice. Why? I’ll explain by discussing the different parts of an Insulated Glass unit. This way I hope to make the whole thing much clearer.

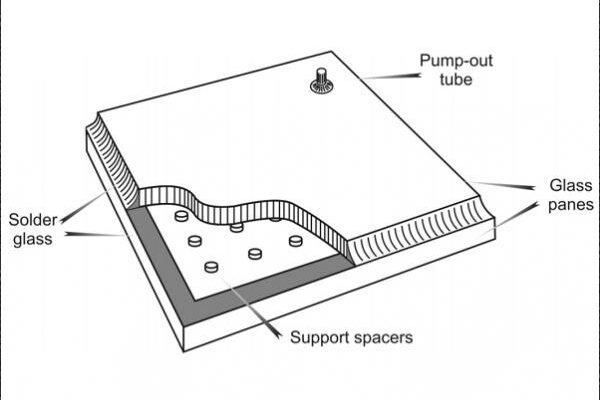

Glass Panes

Tempered glass is normally used because it is several times stronger than regular glass. It goes through intense heat and chemical treatments to give it its core strength and when it’s accidentally broken, it shatters into small harmless fragments instead of sharp shards. Most insulate glass is Low-E coat because they’re primarily use on exterior doors and windows where they are expose to sunlight and winter. It works by reflecting heat back to its source.

Wine cellar doors normally don’t need the benefits of Low-E coating but if your wine cellar is in a place where it can exposed to sunlight, which is the primary source of Ultraviolet Light, you might want to consider Low-E coating. Low-E coating helps in reflecting Ultraviolet Light that can cause unwanted chemical compounds to develop in your wine. In fact, try to avoid any kind of lighting in your custom wine cellar but if you have to, make sure your lighting fixtures are UV free.

Filling

There are 3 ways to fill the space. First, you can use dry air, which is basically air that is free from moisture. Second, is to fill it up with what we call thermal performance gas, and there are three common types: Argon, Krypton and Xenon and all have lower heat transmitting properties than air, Argon being the most popular since it’s the most affordable. These gasses are clear, odorless, non-toxic and chemically stable so they are safe to use. The third way is to create vacuum in between those panes. Technically, it’s very hard to achieve absolute vacuum therefore it tends to be expensive. You can’t go wrong with Argon-filled insulated glass simply because it’s practicality.

Sealants

Sealants have very low moisture vapor transmission rates so are very effective in preventing condensation. They also protect the gas-filled space from glazing and cleaning agents. Butyl is the most commonly use. Some manufactures apply a secondary sealant, which is usually Silicone, to act as structural adhesive for the panes.

Spacer

The spacer is what’s use to separate the glass panes and keep them in place. Historically, manufacturers have been using metallic materials as spacers but this practice undermines the ability of insulated glass to reduce the flow of heat. Look for manufacturers who use spacer materials that do not conduct heat, like structural foam or fiberglass. Additionally, some manufacturers have integrated the processes of adding desiccants and spacers into one simplified step.

Desiccants

You know how silica gels work right? Silica is a type of desiccant that aids in removing trapped moisture within the gas-filled space by absorbing water and hydrocarbons within its vicinity. It’s important that the desiccant used would not absorb or cause chemical reaction with the gas filling.